Bogies, Suspension, Wheels and Axles

| Bonatrans | ||

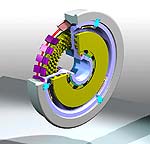

The complete locomotive power wheelset is a system comprised of numerous components. |

The rolling of rail wheels is a precise and computer controlled process. |

Bonatrans rubber-cushioned resilient railway wheel. |

Bonatrans uses Finite Element Analysis (FEA) for railway wheel design. |

Railway wheel design is verified through various laboratory tests. |

|

| Danobat Railway Systems | ||

Automatic flexible line for axle production. |

Double wheel axle-grinding machine. |

High production vertical turning centre. |

High accuracy hub-boring machine. |

High productivity vertical bogie machine. |

|

| Hanson Springs | ||

The most advanced railway spring manufacturing facility worldwide. |

Substantial but closely controlled raw-material stocks allow very short lead-times. |

Whether hand coiled or automatically produced, the quality of every spring matters to Hanson. |

Successful businesses have to continually invest in the future; Hanson Springs has the most up-to-date CNC automatic spring coiling machines in the world. |

Precision spring-end grinding. |

|

| HSW-Zaklad Sprezynownia | ||

HSW- Zaklad Sprezynwnia is a leading international spring manufacturer with more than 70 years' experience in the production of coil springs and suspension springs. |

Our product range includes suspension springs fitted in freight and passenger coaches' and locomotives' bogies. |

We particularly specialise in the production of springs for Y25 bogies. |

Precision hot-coiled springs represent 90%-95% of the entire production at our manufacturing plant. |

||

| Hutchinson Paulstra | ||

Hutchinson Paulstra and Barry Controls are world leaders in antivibration solutions for the railway industry, such as rubber-metal parts for bogies. |

Hutchinson Paulstra has developed a wide range of primary and pneumatic secondary suspensions (air springs, emergency spring and metal parts package) to improve the quality and safety of rail vehicles' ride. |

Hutchinson Paulstra produces items such as bushes, equipped rods,traction mechanisms, anti-roll bars, and engine / equipment suspensions. |

Hutchinson Paulstra also supply resilient elements for low-deck tramway wheels. |

||

| IBEG | ||

BogieMS™ is a bogie precision-measuring system that examines the bogie geometry, axle and wheel parallelism and dynamic load distribution while retaining the manufacturer's specification. |

IBEG's new R2 variable ramp/bridge plate system. |

Movable access step systems range from a one-step system to a complex, high-tech four-step design. |

The foot rest is height-adjustable to provide optimum support. |

The IBEG Sandjet, a sand nozzle for highly efficient sand placement. |

|

| KLW WHEELCO | ||

|

|

|

|

|

|

| Kolowag | ||

Kolowag has 60 years' experience of freight wagons and 26 years' experience in the production of wheel sets. |

We are specialised in railway wheel sets, freight wagons and passenger coaches. |

Kolowag offers railway wheel sets for all types of freight wagons. |

We provide and maintain sleeping and saloon coaches for railways. |

Our freight wagons include open box and hopper wagons. |

|

| KOLTECH | ||

The TUP-650H underfloor wheel lathe. |

TUU 800 / 1250 multi-purpose wheel lathe - for turning the wheel profiles of rail vehicle wheelsets (both new and used) and wheel centres. |

PZK device for performing automatic, contactless measurement and monitoring of flange height and wheel diameters on rail vehicle wheelsets. |

Rail shunter - for shunting rail vehicles on sub-grade sections of the rail where travel with the vehicles' own drives is not possible and their precise positioning is required. |

PZD 150-170 for overlapping rings and securing wheelset tyres. |

|

| MAG | ||

MAG is a market leader in the machining of railroad wheels. |

High-volume manufacturing of railroad wheels is preferably done in three chucking setups. |

We have a twin-spindle machine with reciprocating tool heads for rail wheel manufacturing. |

MAG offers the most suitable machine tool products for manufacturing both railroad wheels and wheelset axles. |

MAG Boehringer and MAG +FMS+ have provided railroad axle manufacturers with innovative process solutions and class-leading CNC equipment for many years. |

|

| MTC | ||

MTC designs and produces rail industry rubber-metal parts for suspension and vibration control systems. |

The company uses the latest technology to fulfil its clients' most demanding requirements. |

MTC provides high-speed, regional and underground rail, tramway, and locomotive rubber-metal parts. |

We can provide customised rubber-metal parts. |

MTC also offers suspension subsystems that generate a greater added-value, allowing for their direct integration into the client's internal processes. |

|

| NENCKI | ||

Bogie load test bench. |

Bogie changing facility. |

Spring test press. |

Testing of the wheel de-railing of vehicles under simulation of a twisted track. |

Rail welding equipment. |

|

| NOSTA | ||

Cold drawn profiles; the semi-finished products for our finished machined parts are produced to high-quality standards. |

Special technical rail components for the boogie or under-floor assembling; coated with Geomed; used for fixing very heavy aggregates under the body. |

Rail connecting parts, created out of a T-slot sliding nut and a 8.8 screw, with exactly defined strength of the connection, e.g. saving costs and assembling time; also used for high-pressure connections. |

Our components and rail assembly system are based on standardised C-rails, press-fitted or for retro fitting. These assembly rails can be supplied in steel, stainless steel or aluminum. At its best, it is extruded together with the car body. |

Pins are one of our segments according to DIN; cylindrical, taper and grooved pins are compliant with DIN / ISO. |

|

| Officine Meccaniche BBM | ||

Double-cylinder fully automatic wheel press. |

Multifunctional bogie testing stand. |

Spring testing press. |

Bogie drop. |

Bogie running testing bench. |

|

| PROMEC | ||

Complete rolling stock bogie. |

Bogie test press. |

Spring test press. |

Frame sill fixture. |

Bolster. |

|

| RAFAMET | ||

The UDA125N portal wheel lathe. |

A UFC wheel lathe with friction roller drive. |

The UGE150N underfloor wheel lathe. |

The KCM150N vertical turning lathe and the WB90 CNC wheel borer. |

Gantry milling centre. |

|

| RBC FRANCE | ||

RBC FRANCE supply spherical plain bearings for high-speed, intercity and regional trains. |

We have also developed a range of new products, spherical plain bearings and elastomeric bearings. |

We supply to both OEMs and end-users. |

We provide a reactive technical support to our customers. |

||

| Ressorts Masselin | ||

Ressorts Masselin provides a wide range of springs manufactured to customer standards. |

Springs for bogie applications are designed by our engineering department before they are manufactured in our factory. |

Springs from 0.2mm to 20mm are usually cold rolled for applications in brake and current capture mechanisms. |

Our anti-roll bar manufacturing line enables us to complete our product range. |

We provide custom springs which are mostly used for track applications. |

|

| Ringrollers | ||

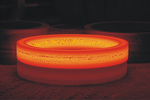

Ringrollers is one of the best forged rail tyre manufacturers worldwide. |

Ringrollers exports more than 50% of its forged railway tyres. |

Ringrollers ensures the safety of rail users by using top-quality materials. |

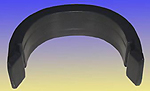

Railway, underground mine railway, light railway and tram forged tyres are amongst our capabilities. |

Other forged products include seamless steel rings used for bearings and gear blanks. |

|

| Scaw | ||

Scaw has the capability to supply a wide range of railway castings. |

Heat treatment on locomotive frames and side frames. |

Machining capabilities for locomotive and passenger bogies. |

Locomotive frames for export to the US. |

Automated wheel plant for manufacture of 34in and 36in monobloc cast steel wheels. |

|

| SCT Europe | ||

High cube container wagon equipped with BLR14.25 bogies. |

BER22.5 with integrated brakes. |

HXA 101.6t GLW coal hopper equipped with BER25.4 Easy Ride bogies. |

Barber S-2-E bogie. |

Barber S-2-HD bogie. |

|

| Suomen Vaimennin | ||

Suomen Vaimennin is a traditional shock absorber manufacturer: we have produced and designed shock absorbers for railway vehicles over 35 years. |

We specialise in primary suspension railway shock absorbers, where relatively small amplitudes and higher velocities confront. |

We can manufacture railway shock absorbers and dampers for every purpose, ensuring that the specific requirements of all customers are met quickly and efficiently. |

Our SV factory offers a covering repair and test service for all of our shock absorbers. |

Our largest test system can perform tests up to 50kN forces and 5m/s velocities on railway shock absorbers and dampers. |

|

| Swasap | ||

Swasap manufactures and supplies railway axles and wheels. |

The company has over 40 years of wheel and axle manufacturing experience. |

Swasap axles are designed and manufactured to perform under the most arduous operating conditions. |

Ultra-modern machinery and equipment at its factory make Swasap one of the finest axle producers in the world. |

||

| Vyksa Steel Works (United Metallurgical Company) | ||

Vyksa Steel Works (VSW) is one of the world's largest manufacturers of railway wheels made of internally produced steel. |

VSW produces more than 140 standard sizes of steel railway wheels. |

We have Europe's largest facilities for producing steel railway wheels. |

In February 2010, VSW put into operation NDT testing for its railway wheels. |

Our steel railway wheels are certified to ISO 9001:2008, ISO 14001:2004 and OHSAS 18001:2007. |

|