|

|

|

|||||||

| Последние сообщения на форуме |

| Последние комментарии к фото |

| Новые записи в дневниках |

| Новые комментарии в дневниках |

| Новое в группах |

| Ссылки сообщества |

| Социальные группы |

| Поиск по форуму |

| Поиск по метке |

| Расширенный поиск |

| Найти все посты, за которые поблагодарили |

| К странице... |

|

#1

|

|

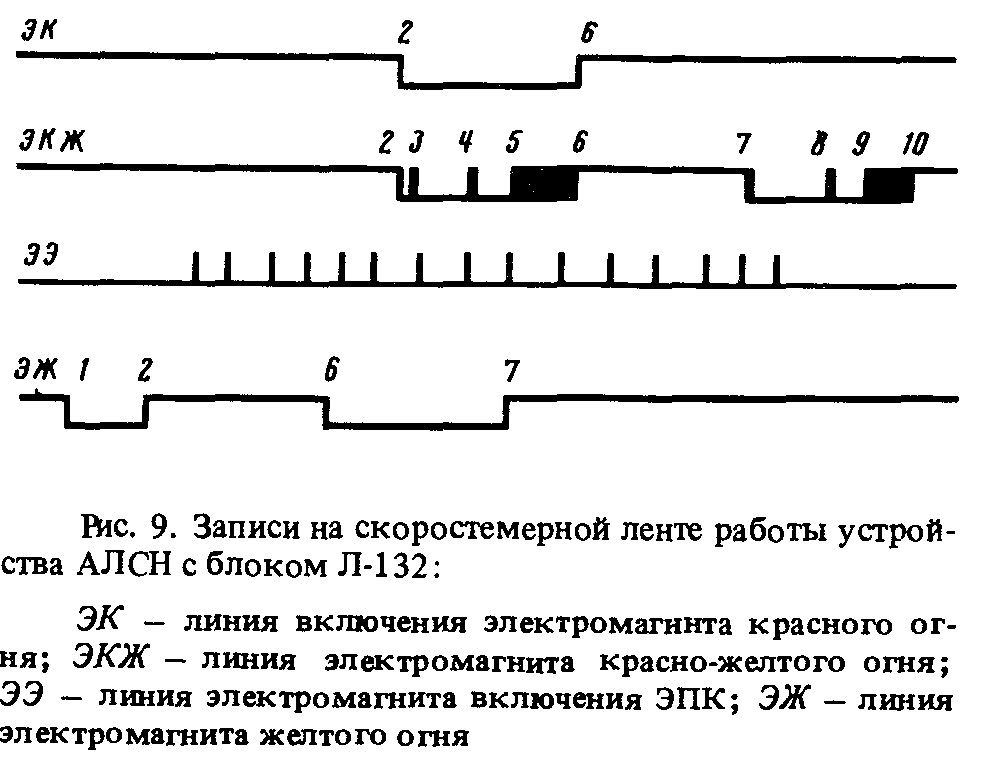

the Control of activity of brakes and АЛСН on скоростемерным to belts Features of records on скоростемерных belts Chart скоростемерная the belt is manufactured by a length of 12 m and breadth 79,5 mms. On it records are effected: speeds, time, pressure of a brake pipe; marks of a backing, self-locking device actuation (ЭЭ), actuations of electromagnets yellow (ЭЖ), red-yellow (ЭКЖ), red (ЭК) fires become, and also sentries pinning. On a belt with a limit of measurement of speed of 150 km/h each millimetre on altitude corresponds 3,75 km/h, and with a limit of 220 km/h - 5,62 km/h. If the belt on 150 km/h has been primed in скоростемер with a limit of measurement of speed of 220 km/h for determination of actual speed value of the speed recorded on a belt multiply by coefficient 1,47 and if the belt on 220 km/h costs in скоростемере on 150 km/h value of the recorded speed multiply by coefficient 0,68. To one millimetre on record altitude on a belt there corresponds pressure variation in a brake pipe on 0,24 kgs/sm2 (at the braking gauge on 6,0 kgs/sm2) or on 0,32 kgs/sm2 (at the braking gauge on 8,0 kgs/sm2), and the altitude between lines of speed of the device on 150 km/h corresponds to pressure variation on 0,64 or 0,85 kgs/sm2 depending on the gauge. Time is determined in a place of the sentry накола and a height of lift of the minute copyist taking into account that 1 mm on altitude corresponds to one minute. The indication of speed is influenced by depreciation of a shroud of a mounted axle. As rotational speed of a wheel with the worn out shroud is more than rotational speed of a wheel with a new shroud at the same speed of motion of the locomotive in the first case скоростемер will show and record the speed which values exceed the real. For reduction of an error of indications because of depreciation of a shroud the drive reduction gearbox скоростемера calculate not for new, and for the shroud worn out approximately half. Diameter of a shroud on which the reduction gearbox is calculated, call settlement For electric locomotives it receive equal 1180 mms, for diesel locomotives — 1010 mms (for CHMEZ - 1030 mms). Knowing actual diameter of a shroud, it is possible to determine an error in record of speed. For example, if settlement diameter of a shroud of 1180 mms, diameter of a new shroud of 1250 mms, and diameter of extremely worn out shroud of 1150 mms the error correction at a new shroud will be 1180:: 1250 = 0,944, and at the worn out shroud 1180:: 1150 = 1,026. At speed of a running of an electric locomotive скоростемер in the first case 94,4 km/h, and in the second 102,6 km/h shows of 100 km/h. Accordingly the belt will be longer or shorter. Besides, скоростемер can not mark on a belt of an alteration of speed in limits to 5 km/h in view of that at engagement of cog-wheels in transfer from the shaft of a speed indicator to a sail batten of the copyist the total gap to 1,2 mms is supposed. As a rule, a metre and the copyist of speed regulate and instal in the device so that the beginning of record of speed necessarily coincided with a line kilometre pinning (zero line). On occasion deflections of record of speed from a line kilometre pinning can happen because of wrong engagement of a sail batten of the copyist to a cog-wheel or sail battens of a segment with a wheel of the shaft of a speed indicator, and also because of incorrect installation of a belt. Thus if the copyist made record of speed above a line kilometre pinning, deflection is necessary (in mm) to increase by scale (in km/h) and the received value to take away from value of the speed recorded писцом. If began records of speed it is disposed below a line kilometre pinning, the value received by similar computations add to the value recorded писцом. So actual speed on the given site is determined on a belt. Correctness of determination of speed check on имеющимся.на to a belt to records of time and the passed way. Thus punching kilometre pinning should correspond to scale of kilometres strictly. If punching pinning it is upset, at calculation consider also this error. Attempts of separate enginemen to change a position or a course of the copyist of speed are easily installed at decoding скоростемерной belts or at check of activity of the device on a bench. Determination of faults of brakes The skorostemernaja belt is the important document on which it is possible to instal as brakes on the locomotive and in a train worked. Especially serious consequences can call faults of the crane of the engineman, influencing activity of brakes of all train. We consider some faults of braking devices which can be discovered at decoding скоростемерных belts. Brake-pipe pressure overestimate at a position of II knob of the crane of the engineman happens more often because of the dropout of air a feed valve of the reduction gearbox and a distribution valve, heavy leakages from the levelling tank or displacement of the knob of the crane towards a position I. If pressure becomes more than 7,0 kgs/sm2 at the pressure gauge on 6 kgs/sm2 on a belt there is a horizontal straight line (fig. 8, and, a line l-l '). Pressure in a main более7,5 kgs/sm2 can call operation of brakes after cutoff of the compressor by the pressure regulator. On fig. 8, and it is visible that the engineman, noticing overestimate, applied a deep stage of braking action, than ensured fast transition to normal charging pressure in a main, золотниковой and the worker air distributor scoops on a flat mode.  Fast or slow rate of liquidation of supercharging pressure leads accordingly to abrupt or flat recession of a line of pressure. And this rate depends not only on stabilising skeg adjustment, but also from the dropout of air the valve of the reduction gearbox and a distribution valve (rate is slowed) or from outflow from the levelling tank and the dropout of air equalising piston seals (rate is expedited, a line 2-3). On fig. 8, both faults are reflected. In the first case fast liquidation of supercharging can call operation of brakes in a train (a point 4), in second — slow rate of release of pressure (the curve 5-6) worsens controllability brakes at frequent braking actions. Recompression in a brake pipe at the knob of the crane of the engineman in a position IV can happen because of air dropout притирочной a surface of a distribution valve or because of origin of thermodynamic processes in the levelling tank. On a belt (fig. 8,) recompression after a stage торможенил (a line 7-8) therefore the engineman has been forced to apply an emergency braking is fixed. Nearby the case of ascending of pressure after its decrease in a main on 1,5 kgs/sm2 is shown. As ascending (a line 9-10) happens slowly (no more than 0,3 kgs/sm2 for 40), brakes will not release in this case. Similar rate of recompression in a main after its discharge is less than on.1,5 kgs/sm2 is inadmissible, as leads, as a rule, to spontaneous holiday of brakes in a train. The similar phenomenon is watched and at low sensitivity of an equalising piston (fig. 8,). In зтом a case at braking action air discharge from a main will be big, than from the levelling tank, and under the influence of a pressure difference the equalising piston displaces downwards and opens a charging valve (a line 11-12). Recompression in a main more than on 0,2-0,3 kgs/sm2 calls complete holiday of brakes on a flat mode. Apparently from fig. 8, г, in the first case at holiday of brakes the engineman did not apply an emergency braking, and in second (approach to prohibiting signal) has been forced to make it. Spontaneous holiday is possible also at short-time moving of the knob of the crane of the engineman to a position VI and its return to a position IV. If at the first stage of braking action there is a sticking (jamming) of an equalising piston, pressure in a main is reduced slowly (fig. 8, д, a line 13-14) therefore brakes can not come to action, especially at good gravity of a braking network. It speaks that at a small pressure difference over and under an equalising piston last cannot mount above the mean position and does not allow to open a relief valve. At deeper stages of braking action the crane of the engineman works normally. Piston jamming can fetch and in step liquidation of supercharging pressure that at heavy leakages of air from a main calls operation of brakes. Step pressure drop can be watched on a belt and by bad activity of the gauge of pressure скоростемера or a hard course of the copyist. Significant outflow of air from the levelling tank or the dropout equalising piston seals can be determined on rate of pressure decline in a brake pipe at a position of IV knob of the crane of the engineman. Rate thus constitutes more than 0,1 kgs/sm2 for 3 mines (fig. 8, a line 2-3 see). The equalising piston thinness is shown after a braking action stage when to existing outflow of air from a braking network outflow through leaky sealing rings of braking cylinders of goods' cars increase. Slow rate of a service braking (less for 1) can be determined than 0,2 kgs/sm2 on a raking line of release of pressure (fig. 8, е, a line 15—16) at high speed of motion. Absence of overestimate of a brake-pipe pressure at holiday of brakes by a position of I knob of the crane (fig. 8, е, a point 17) is a sign of insufficient passableness of air through a block apparatus № 367 or зауживания channels for pass of air from a nutritious main. At a compressor stop along the line the pressure line at first is slowly reduced, and then raises (fig. 8, a line 18-19-20). Apparently on a belt, the engineman did not stop a train, and followed further while the compressor was not actuated. Indistinct fixation of the knob of the crane of the engineman in a position 11 leads to release of pressure (fig. 8, з, a curve 21-22) - the point 22 corresponds to the moment of installation of the knob of the crane in a position I. Mounted axle skidding is characterised by vertical recession of a line of speed (fig. 8, and, a line 23-24—25) and rise of the copyist of time. Accidental operation of the booster of an air distributor № 292 at step braking action calls inverse recompression in mains and holiday of brakes in a train that demands from the engineman of application of the second stage of braking action (fig. 8, to, a line 26-27-28). On a belt it is possible to determine also: disconnection of hoses or main breakage, emergency brake switch failure, overlap of the counter tip crane. The indicated faults are characterised by step pressure drop in a brake pipe; value of recession depends on distance to a damaged area. At main breakage in a head end of train release of pressure will be big (fig. 8, l, a line 29-30), and at breakage in the second part of a train pressure will be installed on 0,2 kgs/sm2 below charging (a line 31-32). At decoding скоростемерных belts it is possible to determine, besides, with enough split-hair accuracy braking pressing in a train. For this purpose there are some methods. The first, the most simple, use when the emergency braking has been along the line applied. Installing but a belt an actual braking distance, knowing a structure of a way and a braking action initial speed, under the nomographs of braking distances fetched in the service instruction of brakes or in rules of thrust calculations, determine actual pressing. So, for example, at a braking distance of 600 m and onset speeds of braking action of 60 km/h on descent of 6 % <гнажатие, determined under nomographs, 30 hardware on 100 т weights of a railroad train will equal. Such method cannot be used at an emergency braking, the applied ambassador of opening of an emergency brake switch in a train, disconnections of hoses and etc. If step braking action braking pressing can be determined roughly under nomographs has been along the line applied or to calculate, receiving that the settlement braking coefficient for freight trains at the first stage of braking action constitutes 30 % of complete value, at the second stage - 50 % and at the third - 70 %. For determination of braking pressing it is convenient to take a site with stopping braking action. For example, if on a belt it has been installed that at application of the second stage of braking action speed decreased or 40 km/h to 0 on descent 10 промилле and the braking distance constituted 500 m under the nomograph settlement braking pressing will be 18 hardware, and taking into account that the braking coefficient constitutes 50 % of complete value, complete pressing on 100 т weights equally 36 hardware. If under the same conditions for a train stop the third stage, braking pressing on 100 т weights of a railroad train equally (18-100:70 = 25,7 hardware has been used. To determine pressing after application of the first stage of braking action under nomographs it is difficult, especially if a braking distance big. In such cases settlement braking pressing of a train determine according to rules of thrust calculations. Condition of brakes in a train can be valued on the way, passed by train at check of action of brakes. At braking coefficient 0,33 braking distance should not exceed set values. The Control of operation АЛСН and скоростемеров Marks about combustion of signal lights of an engineman's indicator place on the upper floor скоростемерной belts. At actuation ЭПК-150 field coil ЭЭ is initiated and the copyist linked to it vertically downwards on 2-2,8 mms transfers. On the same value the copyist of an electromagnet yellow is transferred also or is red-yellow light depending on what fire on an engineman's indicator. Displacement downwards a horizontal line on a belt indicates actuation of a self-locking device or certain fire of an engineman's indicator. At a green light all electromagnets are switched off (except ЭЭ). Knowing an arrangement писцов, it is possible to instal easily what were indications of light signals during this or that moment of a trip. It becomes visually by means of a special template; if necessary it is possible to use nomographs of sites of the circulation with the co-ordinates of an arrangement of travelling light signals put on them, input and exit switches of stations. The malfunction in activity of devices ALSN is indicated by a mark on a belt about combustion of white fire after green, yellow or red-yellow fires. Thus on line ЭЭ at checks of vigilance of the engineman, happening through everyone 30-40 with, vertical hyphens in altitude of 2-2,8 mms are drawn. It is simple to determine and sudden occurrence on an engineman's indicator of red-yellow or red fires after a green light. Thus the engineman is authorised to switch off short-time ЭПК. Consecutive change of fires (green on yellow, yellow on red-yellow and etc.) is considered malfunction in activity АЛСН if it happens on smaller distance, than distance between travelling light signals. Places in the records testifying to occurrence of malfunction ALSN or overlap of a travelling light signal, are marked by the engineman after a trip on the back belts. On belts which are lifted from the locomotives arranged with control units of vigilance with a preliminary indication lamps, it is possible to meet marks about short switching-off ЭПК. It means that pressing an acknowledging contact happened not on a luminous signal, and on whistle ЭПК. At decoding скоростемерной it is possible to instal belts and other factors characterising activity AЛCH and correctness of use by its devices: speed from which vigilance check (about 0,5 or 10 km/h), actuation of a self-locking device by a key or a shut-off cock, operation ЭПК or interruption of its action, button pushing ВК for switching of red fire of an engineman's indicator on white, use by switch DZ is actuated, etc. On a belt activity of all units скоростемера which characteristic faults are is well monitored: vibration of points of speed, wrong record of a brake-pipe pressure, adjustment of the is contact-registering device, wrong adjustment of a tape feed mechanism, absence of record of a backing, sentries pinning, sticking of the copyist of time. Installation not ground писцов, with hard springs, especially in the copyist of time, leads to belt gaps. After trip the engineman should scan attentively records on fast стемерной to a belt and in case of detection of any deflections from the installed requirements to make corresponding marks on its reverse side and in the log-book of technical condition of the locomotive. Decoding of belts at operation Л-132, УКБМ, ИБМ To achieve more complete registration on скоростемерной to a belt of activity of devices ALSN and new devices of security, without increasing thus quantity of electromagnets скоростемера, for fixation of those or other events use simultaneous actuation of two electromagnets or periodic actuation-vyklju-chenie of one of them. Device L-132 . White fire of an engineman's indicator is fixed on fast стемерной to a belt as a result of simultaneous actuation of electromagnets red (ЭК) and red-yellow (ЭКЖ) fires, йздельное actuation of these electromagnets registers on a belt of combustion of corresponding fire. If the assistant of the engineman plunges SП at white or red-yellow fires of an engineman's indicator, on a trace of electromagnet ЭКЖ appear зачерненные bands. At a stop of a train at a prohibiting signal on line ЭКЖ three bands are drawn, as a rule, last of which is wider than the remaining. At the opening of a line signal removing necessity of a stop of a train, on line ЭКЖ there can be one or two short strips. Such registration on a belt скоростемера allows to monitor vigilance not only the engineman, but also its assistant. On fig. 9 the top of skorostemer th belt with record on it of actuation of electromagnets by activity with device L-132 is shown. The point 1 indicates actuation of an electromagnet of a yellow light (ЭЖ); points 2 testify to cutoff ЭЖ and actuation ЭК and ЭКЖ. I.e. about fire on an engineman's indicator of white fire. The strips marked by points 3, 4, reflect short-time (on 5-7) pressing by the assistant of the engineman of the button 5П at occurrence of white fire in an engineman's indicator and a train entrance to prohibiting signal when to the last there are 400 600 m; wide зачерченная the strip beginning in a point 5, indicates a constant button pushing 5Д for 100—200 m to a stop before a prohibiting signal or at passing by its installed order, and also at excess of program speed of a running (see with. 14). Points 6 speak about switching of an engineman's indicator with white on a yellow light; Points 7 — about switching-off yellow and actuation it is red-yellow light (ЭК it is disconnected, the train means follows on red fire of a travelling light signal). The strips marked by points 7, 8, 9, indicate pressing by the assistant of the engineman of button Sn; the point 10 testifies to the cessation of deduction of the button in view of a stop or occurrence on an engineman's indicator of fire permitting motion.  Check of vigilance of the engineman by devices ALCH is conducted by usual order: pressing on РБ it is fixed in the form of primes on line ЭЭ. УКБМ. Registration on a belt of white fire of an engineman's indicator results from actuation of electromagnet ЭК. To determine, what fire was on an engineman's indicator — white or red, it is necessary to find out, whether consecutively electromagnets ЭЖ and ЭКЖ were actuated before it. If actuation and switching-off ЭЖ and ЭКЖ was, means on an engineman's indicator red fire burnt. Executed update УКБМ allows to fix on a belt all pressing by the engineman of an acknowledging contact, a pedal of vigilance or the button of security both on light, and on sound signals. If УКБМ it is disconnected (because of fault or wilfully) vigilance checks happen through 30—40 with at all fires of an engineman's indicator that also it is visible on a belt. Let's consider record possible versions on скоростемерной to a belt by activity AЛCH with УКБМ (fig. 10). Points 1 — automatic switching-off ЭЖ and actuation simultaneously white and red-yellow fires (a running on a station branch track); Points 2 — button pushing Sкж, погасание is red-yellow light also the further running at white fire; Points 3 — switching-off белою and yellow light actuation; Points 4 — switching-off yellow and actuation simultaneously white and red-yellow fires; Point 5 — switching-off is red-yellow light, combustion of one white; Point 6 — short-time switching-off of white fire and actuation red. Only to this sign (switching of fires and pressing on РБ) in this case it is possible to determine occurrence on an engineman's indicator of red fire. I.e. journey of a prohibiting signal; Point 7 — switching-off of red fire, occurrence more permitting; Point 8 — switching AЛCH on white fire (there is no actuation ЭЖ, ЭКЖ); Point 9 — actuation (compulsorily by means of button SkZh) electromagnet ЭКЖ, i.e. a train entrance to prohibiting signal; Point 10 - switching-off by button SKZH EKZH (on a travelling light signal the clear light lighted up); Points 11 - frequent pressing on РБ (ПБ) on a sound signal at dead device UKBM (through 30-40).  ИБМ. Registration of white fire of an engineman's indicator on скоростемерной to a belt as well as in device LT-132 is ensured with simultaneous actuation of electromagnets ЭК and ЭКЖ. If pressing of the lower acknowledging contact happens at flashing of a lamp of a preliminary indication lamps (ИБМ works together with Л-143) or after fire of such lamp (ИБМ works together with УКБМ) on скоростемерной to a belt of additional marks will not be. At the luminous signal dropout at red, red-yellow, white (ДЗ in a position "АЛСН") engineman's indicator fires, and also at red-yellow with fires (ИБМ works together with УКБМ) and pressing by the engineman of the upper acknowledging contact traces of electromagnet ЭЭ the vertical hyphens testifying to analysis of feed circuit ЭПК for the period of pressing of the grip will be white. |

|

|

||||

| Тема | Автор | Раздел | Ответов | Последнее сообщение |

| AUTOMATIC TRAIN CONTROL (Alstom) | Admin | Wiki-Railway | 0 | 18.02.2011 20:32 |

| Providing of trains by brakes | Толян | Wiki | 0 | 05.09.2010 15:02 |

| the Unified automatic control system braking action of trains (SAUT) | Толян | Wiki | 0 | 05.09.2010 14:57 |

| [Статья] Контроль работы тормозов и АЛСН по скоростемерным лентам | Толян | Ж/д статьи | 0 | 19.08.2010 16:59 |

| Возможно вас заинтересует информация по следующим меткам (темам): |

|

,

,

,

,

,

|

| Здесь присутствуют: 1 (пользователей: 0 , гостей: 1) | |

|

|