TTInspect - Automatic Vision Inspection Systems for Trains

|

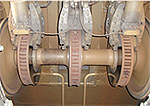

TTInspect is a leading provider of automatic vision inspection systems for trains. It is well known that condition-based maintenance is the most profitable type of maintenance available, but when items have to be visually inspected, this can be costly and inaccurate due to human error. High-resolution vision inspection systemsBy using high-speed and high-resolution vision systems, the repeataÂbility is very high, +/-0.1mm or better, resulting in reliable measurements that can be used to calculate the correct time to chanÂge the part. The reliable data can be used for documentation, providing that mainÂtenance has been close according to specification. Our systems can also improve the environment by, for example, making sure that brake pads are changed when necessary rather than to a timetable, saving many wasted brake pads. Together with our partner companies, we learn from our customers what their requirements are, and offer the right system at the right price and delivery time. The target is always around two years' payback time and at least ten years' lifetime. The systems are more or less maintenance free, due to automatic cleaning and protection systems. The systems are based on more than 25 years' experience within industrial automation, and five years' experience in the train industry. We are, at present, constructing our second generation of inspection systems. Automatic brake pad inspection systemOur automatic brake pad inspection system measures brake pads mounted as axel, wheel or as block brakes. The system has an accuracy of +/-0.1mm at 20km/hr. Fully automatic inspection of brake pads has already shown savings and, at the saÂme time, quick payback on the investÂment of the system. Our systems save 15%-25% on the consumption of brake pads alone. Along with this there are proven savings in labour, since the manual inspection is minimised to checking the system reliability (which it also does itself). An accident where the brake pad falls off the shoe, leaving the shoe pressed into the disc, is hardly ever seen by the operator. Our system, however, will see it automatically, before the accident takes place. With constant inspection every time the train passes the scanning point, it is now possible to bring the pads down to the absolute minimum. At this point the system can send a work order to change pads on a specific axle.  Automatic brake disc inspection systemBrake discs wear a little bit every time the train brakes but the wear is not always in an equal or lineal way, which can often lead to heat damage that can have fatal consequences if not discovered in time. It is most important to pay attention to a train's brake discs. Up until today this has been done manually, which is costly and subject to great variation in results. Using our fully automatic system all brake discs in oÂperation can be inspected every time a train passes oÂver the system. Data is captured and compared equally no matter where the train is inspected. The created database can be used for optimising efficient material disposal and manpoÂwer. At the same time, the reliable database can be used for documentation. People-counting systemsAs well as TTInspect, we also have another company, EuroCount, which deals with people-counting systems and car park guiding systems. Both systems are made from vision technique, or systems based on sensors. People counting is very useful for public transport, in order to share the total revenue between different operators, within a capital city for example. The figures can also be used for material planning and future timetables. Our system guarantees an accuracy of at least 95% and can often realise 99% in real control counts.

TTInspect

Cvr. No.: 28 88 29 20 Tinghøjvej 5 DK-3650 Ølstykke Denmark Tel: +45 47 16 15 00 Fax: +45 47 16 15 50 Email: jt@ttinspect.dk URL: www.ttinspect.dk |

Two screen dumps from the first-generation systems for brake pad inspection. The first is from 2007, before the Danish rail started using the data for changing brake pads. The second is from 2008 where the data is used.  Our automatic brake pad inspection system measures brake pads mounted as axel, wheel or as block brakes. |