Nord-Lock - Wedge Effect Self-Locking Bolts for Rail Subassemblies

|

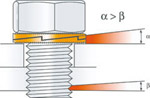

It is vital that joints holding subassemblies together remain secure. Bolts need to be easily removable during maintenance, but resist loosening effects of vibrations and dynamic loads. Wedge-locking action bolt-securing systemsNord-Lock is a leading provider of bolt-securing systems and solutions. We have been collaborating with original equipment manufacturers and contract manufacturers to achieve bolt security for over 25 years. Our main product is a pair of washers that provide a wedge-locking action meeting - a unique method using tension instead of friction (see first picture). On one side the washers have cams with a rise greater than the pitch of the bolt. In addition, there are radial teeth on the opposing washer sides. When the bolt and/or nut is tightened, the teeth grip and seat the mating surfaces. The washers are locked in place, allowing movement only across the face of the cams. Any attempt from the bolt/nut to rotate loose is blocked by the wedge effect of the cams (see second picure). Junker testing of bolt-locking methodsNord-Lock uses a Junker test, which is a comparative test method, according to DIN 65151, in which the joint is subjected to transverse movements while the tension is measured continuously by a load cell. The third picture shows the result of this test when used on a variety of commonly used bolt-locking methods. Customized and standard M3-M130 washersVibration tests with Nord-Lock show a positive result, only some of the initial tension is lost due to normal settlements. The wedge-locking function proves itself when the nut is untightened with a wrench and a clear increase of tension is registered. Nord-Lock washers come in a variety of materials and in sizes ranging from M3-M130. Nord-Lock also develops customized products in collaborations with clients. In the railway industry, Nord-Lock is used in production as well as for maintenance. Examples of common applications with Nord-Lock washers are railway switches, rails, rolling stock components, car connections, maintenance within bogies and breaks, stretcher bars, signal systems and sound barriers. Regular service and maintenance for bolted jointsNord-Lock is especially beneficial for machinery that requires regular service and maintenance. Bolted joints secured with Nord-Lock are easy to untighten with general tools, elements can be lubricated prior to reassembly and the fasteners are reusable. High-purity graphite lubricant for boltsSince Nord-Lock washers do not rely on friction, lubrication has no negative impact on their locking effect. Nord-Lock recommends GTP600 (see picture four), a high-purity graphite lubricant with multiple benefits for the user such as anti-seize compound, low and uniform friction conditions, corrosion protection and heat resistance up to 600°C. Bolts lubricated with GTP600 can easily be dismantled after years of service in extreme conditions. Optimum bolt-locking security in three stepsNord-Lock recommends three simple steps for a smart joint (see picture five):

Nord-Lock is not just a 'problem solver'. Its reliable locking systems are also a guarantee that new problems will not appear. Over the operational lifecycle this gives:

In conclusion, this means higher lifecycle profitability for Nord-Lock users.

Nord-Lock International AB

Box 336 J A Wettergrens gata 7 Gothenburg 401 25 Sweden Tel: +46 31 719 23 00 Fax: +46 31 895847 Email: info@nord-lock.se URL: www.nord-lock.se For More Regional Offices, Please Visit: www.Nord-Lock.com |