DIAB - Sandwich Composite Cores

|

DIAB is a world leader in the provision of innovative sandwich composite solutions that make products light, strong and competitive. In addition to providing high-performance, structural-core materials that have specifically developed for rolling stock applications, the company also supports its global customer base with an extensive series of support services that include laminate design, structural engineering, process optimisation, training and mechanical testing. Railway-specific structural coreAlthough various DIAB cores have been used for many years by leading rolling stock builders and sub-suppliers, the company has recently developed Divinycell P, a railway-specific structural core that meets the latest European regulations regarding fire, smoke and toxicity (FST). Recyclable, thermoplastic sandwich core materialDivinycell P is a recyclable, thermoplastic sandwich core material that is typified by excellent FST properties, a wide processing envelope and very good fatigue properties. It also offers good mechanical characteristics and chemical resistance, low water absorption and good acoustic/thermal insulation. Divinycell P is compatible with most commonly used resin systems (polyester, vinyl ester, epoxy and phenolics) including those with high styrene content. It can also be processed using hand laminating, vacuum bagging and closed moulding processes such as infusion and resin transfer moulding (RTM). With its high residual strength and good dimensional stability at elevated processing temperatures, Divinycell P can be readily used with a wide variety of 'industrial' medium temperature pre-preg systems. Furthermore, it can be thermoformed and used in pultrusion moulding. It is available in densities from 60kg/m³ to 150kg/m³ (3.8lb/ft³ to 9.4lb/ft³) and can be supplied in a variety of thicknesses and finishes to facilitate and speed-up fabrication. Ready-to-use sandwich core construction kitsDivinycell P is also available in ready-to-use construction kits – a concept that was pioneered by DIAB. Here each piece is pre-cut, shaped as necessary and numbered to fit exactly into its designated place in the mould. This approach substantially reduces build times, saves labour costs, improves quality and virtually eliminates waste. Internal and external sandwich cores for structural and non-structural applicationsThe company has been heavily involved in supplying cost-effective solutions to the railway industry for more than 20 years. DIAB sandwich cores can be used both internally and externally for structural and non-structural railway applications. Skirts, nose sections, load-bearing walls, floating floors, seats, tables and luggage racks are just a few of the many possibilities where DIAB sandwich composites can make a substantial contribution to operational efficiency. Sandwich composites based on DIAB cores are one of the best ways to reduce weight in trains, whether they are used for structural members or for a variety of interior panelling. These savings can directly reduce operating costs and minimise environmental impact. DIAB sandwich composites are also inherently stronger than their single-skin equivalents. Moreover, sandwich composites provide excellent acoustic and thermal insulation properties thus eliminating the need for subsidiary materials. Weight-saving sandwich cores for trainsThe weight savings provided by the sandwich concept are exemplified by projects such as the Danish S-Train. By adopting a lightweight philosophy and the DIAB sandwich composites, it has been possible to achieve a 44% weight decrease per seat and an energy reduction of 41% per seat per kilometre, compared with the previous generation of conventional trains. Worldwide support and service for sandwich coresDIAB has 17 strategically located sales and technical support operations and manufacturing units in Australia, China, Ecuador, India, Italy, Lithuania, Sweden, the US and Thailand. No other manufacturer of core materials comes close to offering this level of support and supply chain security.

DIAB International AB

PO Box 201 SE-312 22 Laholm Sweden Tel: +46 430163 00 Fax: +46 430163 96 Email (Europe): info@se.diabgroup.com Email (Asia-Pacific): info@sg.diabgroup.com Email (China): info@cn.diabgroup.com Email (Americas): info@us.diabgroup.com URL: European office URL: Asia-Pacific office URL: Americas ofice URL: Chinese office URL: Italian office |

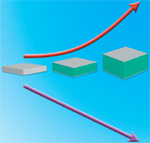

This graphic shows that the greater the core thickness the more stiffness is improved while weight is reduced; all laminates are of equal strength.  Production efficiency is ensured by laying up a composite train front with a 'ready to use' DIAB core kit. |