Pentadyne Power Corporation - Flywheel Energy-Storage Systems

|

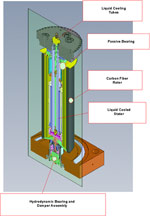

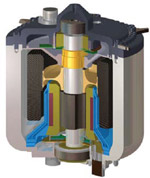

Pentadyne Power Corporation designs, manufactures and markets advanced flywheel energy-storage systems that absorb and regenerate power for rail voltage stabilization and regenerative power recycling applications. The company is the world's leading manufacturer of flywheel energy-storage systems. Designed to provide high power output and energy storage in a compact, self-contained package, Pentadyne rail energy-storage products are a long-lasting, low-maintenance, lightweight and environmentally sound addition/alternative to conventional rail traction power systems. Flywheel energy-storage systems for rail applicationsFlywheel energy-storage systems absorb and release energy very efficiently and quickly, making them perfect for rail applications. They have a wide temperature operating range, last 20 years or longer and have minimal service requirements. They have the following features:

New or retrofit flywheel energy-storage systemsThis flywheel energy-storage system is offered in packaged complete solutions or for retrofit. Packaged solutions included custom-prefabricated traction power substation system Powerblock™ and Tracblock™ products for regenerative energy-storage and voltage-support rail solutions. Wayside energy-storage systemsToday's new trains require more power and also have regenerative braking capabilities. In addition, with ridership increasing and transit agencies running more or longer trains, a greater demand is being placed on rail traction power systems. By using wayside energy-storage systems to support rail track voltage, you get the added speed and performance to optimize your investment in rolling stock and improve service. By capturing the regenerative braking energy and then using it when needed to accelerate the same or other trains, you save energy, eliminate under/overvoltage conditions and cut the use of resistor banks (which waste regenerative energy and provide unwanted heat in stations and underground structures). Energy-storage substationsEnergy-storage substations can tie directly to the DC rail, simplifying installation and offering location flexibility. The flywheels are arranged along the walls of the substation building with access for personnel from the front. Flywheels are connected in parallel to match traction power and train specifications and power is fed to inductor and DC breakers at opposite end of structure. A distribution panel provides power to lighting and auxiliary equipment. The only problem has been the availability of a robust and proven energy-storage technology that can do the job. Today's battery technologies can't meet the heavy duty cycling and long life cycle requirements for mass transit. Ultra-capacitor cells are limited in energy capacity and introduce thousands of points of failure. Flexible flywheel energy-storage systemsPentadyne flywheel energy-storage systems offer the ultimate flexible solution for transit agencies, engineering firms and equipment suppliers looking for a green energy-saving solution for the rail traction power application. These systems can assist in reducing operational costs (traction power is generally the largest component of a transit agency electric bill) and greenhouse gas emissions (thus providing future carbon credits). They can be installed at a lower cost than traditional solutions, providing additional capital cost savings. Award-winning flywheel energy-storage systemsThe company has sold and shipped more than 1,000 flywheel systems since 2004. Pentadyne was named a 2007 Technology Pioneer by the World Economic Forum, and its flywheel product has also won numerous design awards.

Pentadyne Power Corporation

20750 Lassen St Chatsworth California USA Contact: Chandler Williamson (vice-president business development) Tel: +1 818 350 0370 Fax: +1 818 350 0385 Email: chandler.williamson@pentadyne.com URL: www.pentadyne.com |