|

|

|

|||||||

|

|

#1 (ссылка) |

|

Crow indian

Регистрация: 21.02.2009

Возраст: 40

Сообщений: 30,038

Поблагодарил: 398 раз(а)

Поблагодарили 5987 раз(а)

Фотоальбомы:

2576 фото

Записей в дневнике: 698

Репутация: 126089

|

Тема: On the issue of the effectiveness of lubricating means for rails and wheels of traction rolling stockOn the issue of the effectiveness of lubricating means for rails and wheels of traction rolling stock V.S. Kossov, Doctor of Technical Sciences, Professor, General Director, Yu.I. KLIMENKO, Ph.D. technical, science, head of department, Yu.A. PANIN, Ph.D. technical, science, head of department, A.V. TRIFONOV, Ph.D. technical, science, deputy head of department, A.Yu. PANIN, category 1 engineer, JSC Research and Design-Technological Institute of Rolling Stock (JSC VNIKTI, Kolomna) The most important priorities for JSC Russian Railways are the development of promising train traffic with guaranteed traffic safety and increasing operational efficiency based on optimizing the interaction of track services and rolling stock [1]. The interaction of rolling stock wheels and rails is a fundamental physical process during the movement of locomotives and cars on railways. The interaction conditions in the “wheel-rail” system have a significant impact on the service life and organization of maintenance of the main track devices and rolling stock, as well as on the operating costs of railways [2].  The relevance of numerous studies on the problem of interaction between rolling stock wheels and rails, carried out in Russia and abroad, as well as ongoing at present, is due to the fact that this problem, in addition to the purely economic aspect (loss of energy resources to overcome movement resistance, wear of wheels, rails) etc.), is closely related to traffic safety in railway transport [3]. There are two main measures to reduce the wear of wheel flanges - reducing the coefficient of friction in the contact of the flange with the side surface of the rail (ridge and rail lubrication) and reducing the angle of approach of the guide wheelsets on the outer rail due to their passive or active rotation in the bogie frame (radial wheel installation pairs) [4]. In 2010, JSC "VNIKTI" together with the Scientific Research Institute of Railway Transport (JSC "VNIIZhT") carried out comparative tests of lubricants (grades KR-400, MS-27, CP-KU and PUMA-MR) for lubricating the side face of the head on external rail in a curve. The best indicators in terms of wear resistance and purchase price were lubricants KR-400 and MS-27 [5].  Based on the test results, the wear resistance values of the KR-400 and MS-27 lubricants were obtained at the level of 20.8 and 20.5 thousand rolling stock axles, respectively, which is approximately equal to the passage of about 72 trains with 71 cars each or a tonnage of about 50 million tons. gross (currently the wear resistance is about 30 thousand rolling stock axles, and the load capacity is about 72 million tons gross). In Fig. Figure 1 shows the wear resistance of KR-400 lubricants at a lubricant consumption of 420 ml/km on the Experimental ring of JSC VNIIZhT. It can be seen that the wear resistance at a given flow rate is about 30 thousand rolling stock axles. According to the “Concept for the development of technology for lubricating the wheel-rail contact zone” at JSC Russian Railways [6], the number of passes of rail lubricating cars should be: at least one every two days in areas with a cargo load of up to 45 million tons gross; one per day in areas with a cargo load of 45 ... 80 million tons gross; three times every two days in areas with a cargo load of more than 80 million tons gross. The lubricant consumption should be 150 ... 350 g/km of lubricated track, depending on the degree of wear of the side face of the rail head [5]. In Fig. Figure 2 shows the effectiveness of rail lubrication with RS-6 lubricant for VL 10 electric locomotives after implementation on the Moscow Railway. It is noteworthy that this is a pure experiment. At the time of the introduction of lubricating technology on the Moscow road by rail lubricating locomotives in the Bekasovo locomotive depot, there were no other technical and technological devices for lubricating or strengthening the flanges of locomotive wheels. As a result, wear on locomotive wheel flanges decreased by 3–4 times. In Fig. Figure 3 shows the dependence of wear on the wheel flanges of electric locomotives VL 10 on the Moscow road on the amount of RS-6 lubricant consumed. Loko wheel flange wear motive is inversely related to the amount of lubricant consumed. In other words, as the amount of lubricant increases, wear decreases, and vice versa. In table 1 presents an analysis of ridge and rail lubrication products on roads with problematic wear of locomotive wheels for 2021-2022. From the analysis of the data presented in table. 1, it follows that for each kilometer of a lubricated rail, the lubricant consumption of 350 g/km recommended by the Concept [6] is not used anywhere. The wear rate of locomotive wheel flanges and lubricant consumption by flange lubrication devices on some roads (East Siberian, Transbaikal, Far Eastern, North Caucasian) is shown in Fig. 4. From the analysis of these histograms it follows that for electric locomotives ZES5K on the Trans-Baikal Railway in 2022, wear has increased in direct proportion to the consumption of lubricants used for ridge lubrication. In Fig. Figure 5 shows the influence of radial wheel set devices (RWPD) on wear of locomotive wheel flanges. The comparison presents three types of locomotives: 2TE25A, equipped with RUKP devices, 2TE25KM and 2TE116 without RUKP devices. The effectiveness of the RUCP devices installed on the 2TE25A is clearly visible, which is consistent with the tests carried out by specialists from JSC VNIKTI in 2012. When conducting comparative tests in 2012, it was found that the wear rate of the wheel flanges of the wheel pair of the 2TE25A diesel locomotive equipped with RUCP devices was 0.252 mm/10 thousand km, which is 2.3 times less than the similar indicator for ZTE10KM diesel locomotives with AGS-8 (0.571 mm/10 thousand km) and 2.7 times less than the value of the same indicator for diesel locomotives ZTE10MK without AGS-8 (0.688 mm/10 thousand km). In table Figure 2 presents the results of computer simulation of locomotives with wheel diameters of 1050 mm and 1250 mm passing a curve with a radius of 300 m at a speed of 70 km/h. From the analysis of the results of computer modeling of locomotives passing the curve R = 300 m at a speed of 70 km/h, it follows that lubrication of the contact zone of the side face of the outer rail with the flange of the locomotive wheel significantly reduces friction indicators. It also follows from the analysis that lubrication reduces the friction indicators of both an electric locomotive wheel with a diameter of 1250 mm and a diesel locomotive wheel with a diameter of 1050 mm by an average of 63%. On the roads of the JSC Russian Railways network, locomotives with axle-by-axle traction force control are used. The axial control system can be characterized by its main qualities - equalizing the coefficient of traction utilization along the axes and limiting the excess angular speed of sliding of the wheel pairs. The effect of these properties of the axle control system is to increase traction properties and reduce wear of tires on wheel sets.  The process of tribological contact of the wheel tire with the rail is determined by phases depending on the speed of mutual movement:

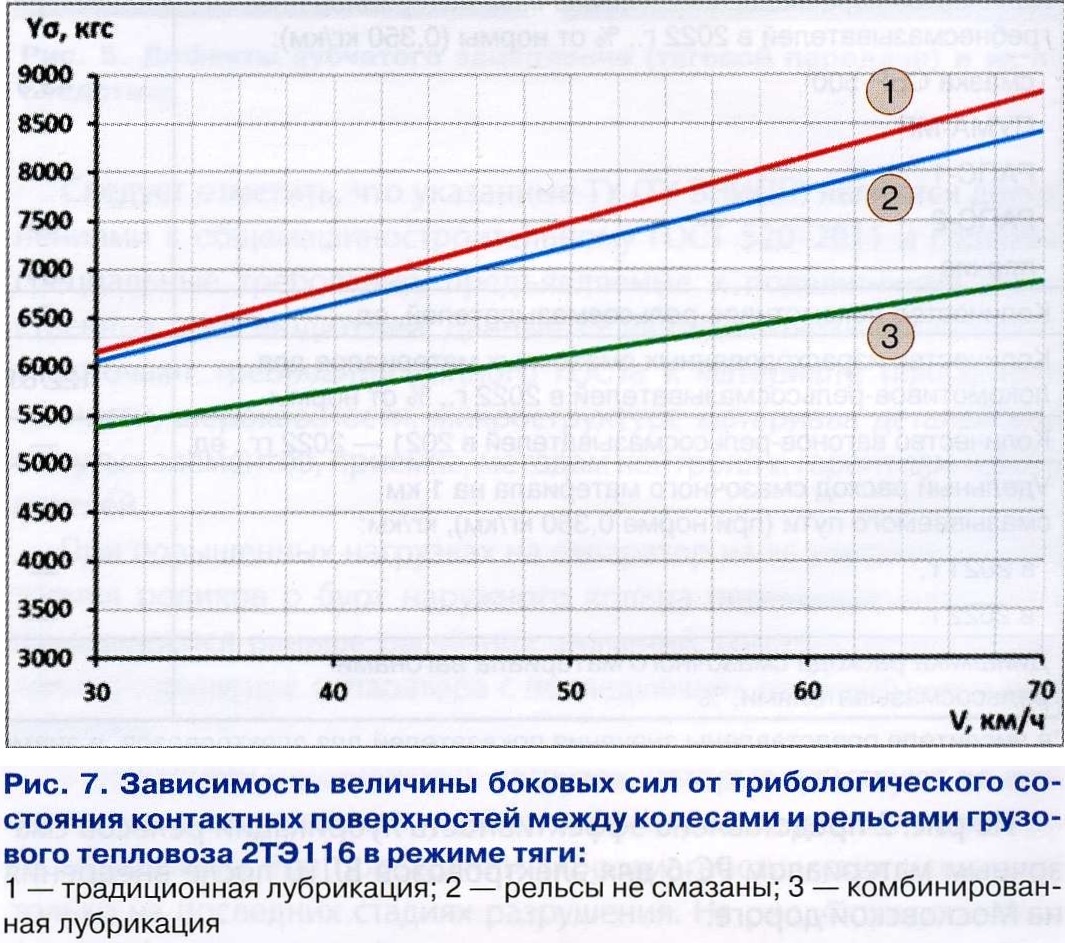

In order to increase the efficiency of rail lubrication, JSC VNIKTI proposes the use of combined rail lubrication technology (Fig. 6):

Based on the results of the experiment, it was established that traditional rail lubrication increases the impact of rolling stock on the track by up to 5%, and combined lubrication reduces it by up to 33%, depending on the speed of movement and the operating mode of the train [8]. Bibliography 1. Manturova E.A. Saving fuel and energy resources due to the use of nanomaterials in lubrication technologies in railway transport // Youth and science: Collection of materials of the VII All-Russian scientific and technical conference of students, graduate students and young scientists, dedicated to the 50th anniversary of the first human flight into space. - Krasnoyarsk: Siberian Federal University, 2011. - URL: https://conf. sfu-kras.ru/sites/mn2011/thesis/s1/s1_35.pdf (date of access: 05/05/2023). 2. Druzhinina O.V. Algorithm for analyzing the stability of a model of dynamic interaction between a train and a railway track under seismic impacts / Druzhinina O.V., Klimova D.V., Mulkidzhan A.S. // Science and technology of transport. - 2011. - No. 4. - P. 24 - 32. 3. Panin Yu.A. Reducing the lateral impact of rolling stock on the track using combined rail lubrication: specialty 05.22.07 “Railway rolling stock, train traction and electrification”: dis. ...cand. technical, science / Panin Yuri Alektinovich; FSUE "VNIKTI" Ministry of Railways of Russia. - Kolomna, 2005. - 174 p. 4. Mikhalchenko G.S. Assessing the wear of wheels of a freight diesel locomotive with a radial installation of wheel pairs / Mikhalchenko G.S., Yurshin A.S. // Bulletin of BSTU. - 2007. - No. 2. - P. 39 - 43. 5. Markov D.P. Testing of rail lubricants on the Experimental Ring of JSC VNIIZhT // Industrial transport XXI century. - 2012. - No. 1. - P. 49 - 52. 6. Concept for the development of technology for lubricating the “wheel-rail” contact zone at JSC Russian Railways. - Approved On January 16, 2015, by order of JSC Russian Railways No. 60r. 7. Kossov V.S. Lubrication of rails and impact on the track of rolling stock / Panin Yu.A., Trifonov A.V., Ponomarev A.S., Panin A.Yu. // Railway transport. - 2022. -No. 7. -S. 48 -51. 8. Lubrication of rails by a traction locomotive as part of a train / Kossov V.S., Lunin A.A., Panin Yu.A., Trifonov A.V., Ilyin I.E. // Bulletin of Scientific Research. Institute of Railways transport - 2017. - No. 1. -WITH. 57 -60. |

|

|

Цитировать 12 |

|

|

||||

| Тема | Автор | Раздел | Ответов | Последнее сообщение |

| = RW-Locomotive = Updating infrastructure facilities of the Traction Directorate | Admin | Article-RW | 0 | 10.12.2023 16:41 |

| Practical railway engineering. Rolling Stock | Admin | Wiki | 0 | 02.07.2013 07:12 |

| RAILWAYS AND WAR before 1918. STANDARD GAUGE FREIGHT ROLLING-STOCK (U.K.) | Admin | Wiki | 0 | 18.02.2011 15:58 |

| Ответить в этой теме Перейти в раздел этой темы Translate to English |

| Здесь присутствуют: 1 (пользователей: 0 , гостей: 1) | |

|

|